The Role of Disc Pin Insulators in High Voltage Applications

2025-12-14 5:37:24

Today, our company welcomed important clients from many countries to visit and inspect our factory. This is a significant milestone for our company's global reach, and a moment to showcase our strength and achievements. We are deeply honored and are full of confidence for the future.

The Role of Disc Pin Insulators in High Voltage Applications

Understanding Disc Pin Insulators

Disc pin insulators play a crucial role in ensuring the reliability and safety of electrical transmission and distribution systems. These insulators are specifically designed to support high voltage lines while preventing electrical leakage and providing mechanical stability. In this article, we will delve into the various aspects of disc pin insulators, their construction, operational benefits, and specific applications in high voltage scenarios.

What Are Disc Pin Insulators?

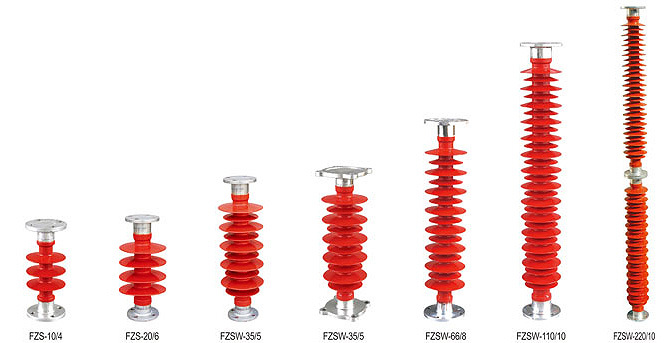

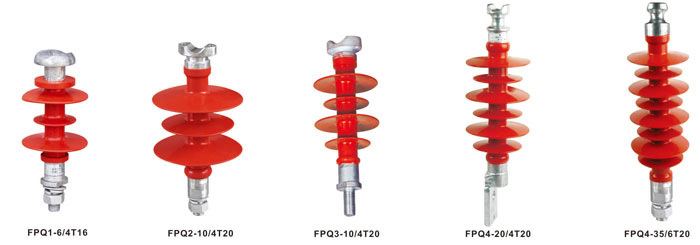

Disc pin insulators are specialized devices used in electrical systems to maintain the necessary distance between live wires and grounded structures. They are typically made from materials that have excellent insulating properties, ensuring minimal energy loss. Their design consists of a series of disc-shaped components stacked together, which enhances their electrical and mechanical characteristics.

Construction of Disc Pin Insulators

The construction of disc pin insulators involves a variety of materials, primarily ceramics, glass, and polymer compounds. Each material serves a specific purpose and is chosen based on the application's requirements:

- **Ceramic Insulators**: These are known for their exceptional durability and resistance to environmental conditions. Ceramic provides excellent electrical insulation, making it ideal for high voltage applications.

- **Glass Insulators**: Glass is often used for its transparency and strength. It can withstand harsh weather conditions and is less prone to damage from environmental factors.

- **Polymer Insulators**: These are becoming increasingly popular due to their lightweight nature and resistance to pollution. Polymer insulators are designed to be hydrophobic, minimizing water retention, which can lead to electrical failures.

Types of Disc Pin Insulators

There are several types of disc pin insulators available, each tailored for specific uses:

- **Suspension Insulators**: Used to suspend overhead high voltage lines from towers, allowing flexibility and reducing mechanical stress.

- **Line Post Insulators**: Fixed on poles to provide support and electrical insulation for high voltage lines.

- **Strain Insulators**: Designed to handle tension in the transmission lines, ensuring stable operation.

Importance of Disc Pin Insulators in High Voltage Applications

Disc pin insulators are indispensable in high voltage applications for several reasons:

1. Electrical Safety

The primary function of disc pin insulators is to ensure electrical safety. By providing a barrier between conductive materials and the environment, these insulators prevent electrical arcing and short circuits, thereby protecting infrastructure and human life.

2. Mechanical Strength

High voltage applications can subject insulators to significant mechanical stress due to wind, ice, and other environmental factors. Disc pin insulators are designed to withstand these forces, ensuring the stability and integrity of the electrical system.

3. Environmental Resistance

Disc pin insulators are engineered to resist various environmental factors, including moisture, pollution, and extreme temperatures. This durability ensures a longer lifespan and lower maintenance costs for electrical systems.

Applications of Disc Pin Insulators

Disc pin insulators are utilized in various high voltage applications across different sectors:

1. Power Transmission Lines

In power transmission networks, disc pin insulators support overhead lines, ensuring that conductors remain insulated from the ground and other structures. This application is critical for maintaining the efficiency and safety of electricity distribution over long distances.

2. Substation Equipment

Disc pin insulators are commonly used in substations to support transformers, circuit breakers, and other high voltage equipment. Their ability to withstand high voltages while providing mechanical support is essential in these critical areas.

3. Renewable Energy Systems

With the rise of renewable energy sources, particularly wind and solar, the demand for reliable electrical components has increased. Disc pin insulators play a vital role in the infrastructure of wind farms and solar energy plants, ensuring safety and efficiency.

Performance Metrics of Disc Pin Insulators

When evaluating disc pin insulators, several performance metrics should be considered:

1. Voltage Rating

The voltage rating indicates the maximum voltage an insulator can handle without failure. It's crucial to select an insulator with a voltage rating suitable for the specific application.

2. Mechanical Strength

Mechanical strength is measured in terms of the insulator's ability to withstand tensile and compressive forces. This characteristic is vital in high voltage applications where environmental stressors are prevalent.

3. Hydrophobicity

Hydrophobic properties help in reducing contamination and water absorption, leading to improved performance in polluted environments. Insulators with high hydrophobicity are less likely to experience failures due to water retention.

Factors Influencing the Selection of Disc Pin Insulators

Selecting the appropriate disc pin insulator for a high voltage application involves considering several factors:

1. Environmental Conditions

The environmental conditions, including humidity, temperature fluctuations, and pollution levels, significantly influence the choice of insulator material. For instance, polymer insulators may be more suitable in highly polluted areas due to their hydrophobic nature.

2. Application Requirements

Understanding the specific requirements of the application, such as voltage levels and mechanical stress, is essential for selecting the right type of insulator. Different types offer distinct advantages depending on the operational environment.

3. Regulatory Standards

Compliance with industry standards and regulations is critical when selecting insulators. Ensuring that the chosen insulators meet safety and performance standards can prevent future liability issues.

Maintenance of Disc Pin Insulators

Regular maintenance of disc pin insulators is essential for ensuring their long-term performance and reliability.

1. Visual Inspections

Conducting routine visual inspections can help identify signs of wear and damage, such as cracks or contamination. Early detection of these issues can prevent major failures.

2. Cleaning Procedures

In areas with high pollution levels, periodic cleaning of insulators may be necessary to remove dirt and contaminants that can compromise their performance. This process should be done carefully to avoid damaging the insulator.

3. Replacement Protocols

Establishing a clear replacement protocol for damaged or worn insulators is vital. Keeping an inventory of spare parts can ensure prompt replacements, minimizing downtime in the electrical system.

Conclusion

In the realm of high voltage applications, disc pin insulators are an essential component that ensures safety, reliability, and efficiency. Their unique construction, durability, and adaptability make them suitable for a wide range of applications, from power transmission lines to renewable energy systems. Understanding their role, performance metrics, and maintenance requirements can help engineers and operators make informed decisions when selecting the right insulator for their specific needs. By prioritizing quality and adhering to industry standards, we can enhance the performance and lifespan of our electrical infrastructure, ultimately leading to a safer and more efficient energy distribution system.

FAQs

1. What is the primary function of disc pin insulators?

Disc pin insulators primarily serve to provide electrical insulation between live wires and grounded structures, preventing electrical leakage and ensuring safety.

2. What materials are used in the construction of disc pin insulators?

Disc pin insulators are typically made from ceramics, glass, or polymer compounds, each chosen for their insulating properties and environmental resistance.

3. How do environmental conditions affect disc pin insulators?

Environmental conditions such as humidity, pollution, and temperature fluctuations can influence the performance and durability of disc pin insulators. Selecting the right material is crucial for specific environmental challenges.

4. What are the maintenance requirements for disc pin insulators?

Regular visual inspections, cleaning procedures, and a clear replacement protocol for damaged insulators are essential for maintaining their performance and reliability.

5. Are there different types of disc pin insulators for various applications?

Yes, there are different types of disc pin insulators, including suspension, line post, and strain insulators, each designed for specific applications and operational requirements.

Key words:

Related News

Understanding the Importance and Functionality of Pin Insulators in Electrical Systems

Pin insulators are essential components in the electrical engineering domain, particularly within overhead power line systems. These insulators serve a fundamental purpose: to support conductors and provide electrical insulation, ensuring safe and efficient energy transmission. Understanding their functionality and significance can greatly enhance the reliability and performance of electrical networks.

2025-12-14 5:24:46

china porcelain ceramic insulators

In electrical insulation, proven heritage meets modern engineering. For generations, porcelain ceramic insulators have been the global standard for safety and durability in overhead power line applications. Their enduring popularity stems from a perfect synergy of material science and practical performance.

2025-12-14 5:41:07