Choosing the Right Disc Pin Insulator for Your Electrical Needs: A Comprehensive Guide

2025-12-14 5:42:34

Today, our company welcomed important clients from many countries to visit and inspect our factory. This is a significant milestone for our company's global reach, and a moment to showcase our strength and achievements. We are deeply honored and are full of confidence for the future.

Choosing the Right Disc Pin Insulator for Your Electrical Needs

When it comes to electrical installations, selecting the appropriate components is crucial for ensuring safety, efficiency, and longevity. Among these components, **disc pin insulators** play a significant role in maintaining the integrity and functionality of electrical systems. This article serves as a comprehensive guide to help you choose the right disc pin insulator for your unique electrical needs.

Table of Contents

1. Understanding Disc Pin Insulators

2. Types of Disc Pin Insulators

- 2.1 Material Types

- 2.2 Design Variations

3. Applications of Disc Pin Insulators

4. Key Factors to Consider When Choosing Insulators

- 4.1 Electrical Strength

- 4.2 Mechanical Strength

- 4.3 Environmental Conditions

5. Installation Guide for Disc Pin Insulators

6. Maintenance and Inspection

7. Common Mistakes to Avoid

8. FAQs

9. Conclusion

Understanding Disc Pin Insulators

Disc pin insulators are essential components in electrical systems, primarily used to support and insulate conductors in overhead power lines and substations. These insulators provide mechanical support while preventing electrical contact with grounded structures, ensuring safe transmission of electricity. Their unique design, which resembles a disc, allows them to handle high voltage and environmental stress effectively.

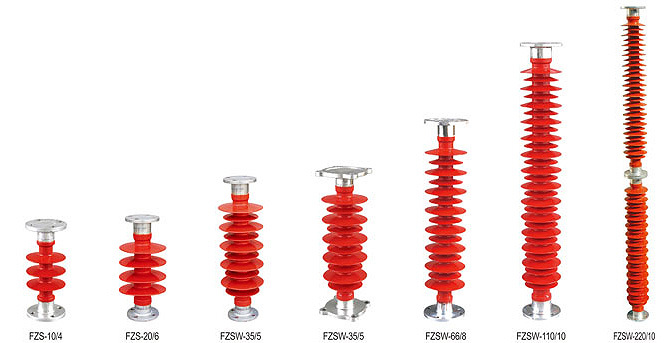

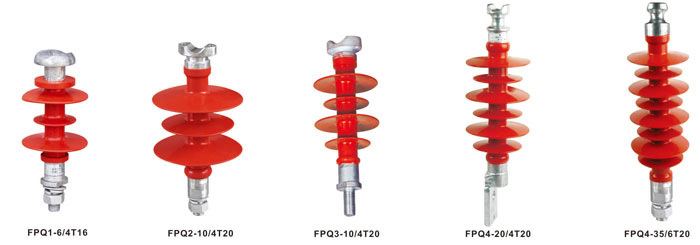

Types of Disc Pin Insulators

Choosing the right type of disc pin insulator is fundamental to the performance of your electrical system. There are various types classified primarily by **material types** and **design variations**.

Material Types

1. **Porcelain Insulators**: Known for their high dielectric strength and thermal stability, porcelain insulators are widely used in high-voltage applications. They are resistant to weathering and can withstand extreme temperatures.

2. **Glass Insulators**: Glass insulators offer excellent electrical properties and transparency, allowing for easy visual inspection. They are resistant to UV radiation and corrosion but are heavier compared to other materials.

3. **Polymer Insulators**: Made from advanced polymer materials, these insulators are lightweight and resistant to environmental degradation. They offer superior flexibility and can handle a range of electrical stresses, making them ideal for various applications.

Design Variations

Disc pin insulators are available in various designs that cater to different requirements:

- **Single-disc Insulators**: Used for lower voltage applications, they provide basic support and insulation.

- **Multi-disc Insulators**: These insulators are stacked to achieve higher insulation strength, making them suitable for high-voltage lines.

- **Suspension Insulators**: Designed to hold conductors suspended from towers or poles, these insulators are crucial for overhead line systems.

Applications of Disc Pin Insulators

Disc pin insulators are versatile and find applications across various sectors:

- **Power Transmission**: They are primarily used in overhead power lines to support conductors and provide insulation.

- **Renewable Energy**: In solar and wind energy installations, these insulators help maintain system integrity.

- **Telecommunications**: Used in communication lines to support and insulate cables, ensuring signal integrity and reliability.

Key Factors to Consider When Choosing Insulators

When selecting a disc pin insulator, several key factors must be evaluated to ensure optimal performance.

Electrical Strength

The electrical strength of an insulator is paramount. It must withstand the operating voltage without breaking down. Always check the manufacturer’s specifications for rated voltage and compare it with your system requirements.

Mechanical Strength

Mechanical strength refers to the insulator's ability to withstand physical stress, such as wind, ice, and conductor tension. Choose insulators with high tensile strength for environments prone to such conditions.

Environmental Conditions

Consider the environmental conditions where the insulators will be deployed. Factors like humidity, temperature extremes, and pollution levels can significantly affect an insulator’s performance and longevity.

Installation Guide for Disc Pin Insulators

Proper installation of disc pin insulators is critical for their performance and reliability.

1. **Preparation**: Ensure the installation site is clear of debris. Verify that the insulator type matches the application requirements.

2. **Mounting**: Secure the insulator to the designated support structure, ensuring it is correctly aligned to hold the conductor.

3. **Connecting Conductors**: Carefully attach the conductors to the insulator, maintaining the recommended tension levels.

4. **Final Inspection**: Conduct a thorough inspection to ensure all components are secure and correctly positioned.

Maintenance and Inspection

Regular maintenance and inspection of disc pin insulators are essential for long-term performance.

- **Visual Inspections**: Periodically check for signs of wear, cracks, or contamination. Look for signs of tracking or flashover, especially in polluted environments.

- **Cleaning**: In areas with high pollution, insulators should be cleaned to remove contaminants that can affect their performance.

- **Testing**: Conduct electrical tests to assess the insulator's integrity and dielectric strength.

Common Mistakes to Avoid

1. **Ignoring Specifications**: Always adhere to manufacturer specifications to avoid installing insulators not suited for your application.

2. **Overlooking Environmental Factors**: Failing to consider environmental conditions can lead to premature failure of insulators.

3. **Neglecting Maintenance**: Regular inspection and maintenance are crucial for extending the lifespan of insulators.

FAQs

1. **What is a disc pin insulator?**

A disc pin insulator is a device used in electrical systems to provide mechanical support and electrical insulation for conductors.

2. **What materials are disc pin insulators made from?**

They are commonly made from porcelain, glass, or polymer materials, each offering unique properties suited for different applications.

3. **How do I determine the right insulator for my project?**

Consider factors such as voltage rating, mechanical strength requirements, and environmental conditions to select the appropriate insulator.

4. **Can disc pin insulators be used in high-voltage applications?**

Yes, multi-disc insulators are specifically designed to handle high voltages and are widely used in power transmission lines.

5. **How often should I inspect disc pin insulators?**

Regular inspections should be conducted at least once a year, with more frequent checks in polluted or harsh environments.

Conclusion

Choosing the right disc pin insulator is a critical decision in any electrical installation. By understanding the various types, applications, and key factors to consider, you can make an informed choice that enhances the effectiveness and safety of your electrical systems. Regular maintenance and inspection will further ensure that your insulators provide the reliable performance you need over the long term. By following the guidelines outlined in this article, we are confident that you will be well-equipped to select the best disc pin insulator for your electrical needs.

Related News

Understanding the Importance and Functionality of Pin Insulators in Electrical Systems

Pin insulators are essential components in the electrical engineering domain, particularly within overhead power line systems. These insulators serve a fundamental purpose: to support conductors and provide electrical insulation, ensuring safe and efficient energy transmission. Understanding their functionality and significance can greatly enhance the reliability and performance of electrical networks.

2025-12-14 5:24:46

The Role of Disc Pin Insulators in High Voltage Applications

Disc pin insulators play a crucial role in ensuring the reliability and safety of electrical transmission and distribution systems. These insulators are specifically designed to support high voltage lines while preventing electrical leakage and providing mechanical stability.

2025-12-14 5:37:24